AI Manufacturing, In an age of soaring consumer expectations, businesses face a critical challenge: how to deliver personalized products and services at scale without compromising efficiency or profitability. Enter artificial intelligence (AI), a transformative force driving the evolution of custom manufacturing and revolutionizing the way we think about production and personalization.

The Demand for Personalization

The modern consumer no longer settles for one-size-fits-all solutions. From bespoke clothing to tailored home décor, personalization has become a baseline expectation. According to a McKinsey report, 71% of consumers expect companies to deliver personalized interactions, and 76% get frustrated when this doesn’t happen. This demand is not limited to luxury markets; it permeates the automotive and healthcare industries.

However, meeting this demand at scale has traditionally been a logistical and financial nightmare. Customization often requires unique tooling, specialized labor, and extended production timelines—all of which inflate costs. This is where AI steps in as the game-changer.

How AI Powers Custom Manufacturing

AI-driven technologies are enabling manufacturers to combine the efficiency of mass production with the uniqueness of bespoke craftsmanship. Here’s how:

1. Data-Driven Design

AI systems can analyze vast consumer data to identify trends and preferences. For example, an AI algorithm can process data from social media, online reviews, and purchase histories to predict what designs, features, or colors a target audience will favor. This enables manufacturers to create products that feel uniquely personal while still appealing to broader market segments.

2. Generative Design and Prototyping

AI-powered generative design tools allow manufacturers to create thousands of design iterations in a fraction of the time it would take human designers. These systems use constraints such as material type, cost, and functionality to generate optimal designs, speeding up the prototyping process and reducing time-to-market.

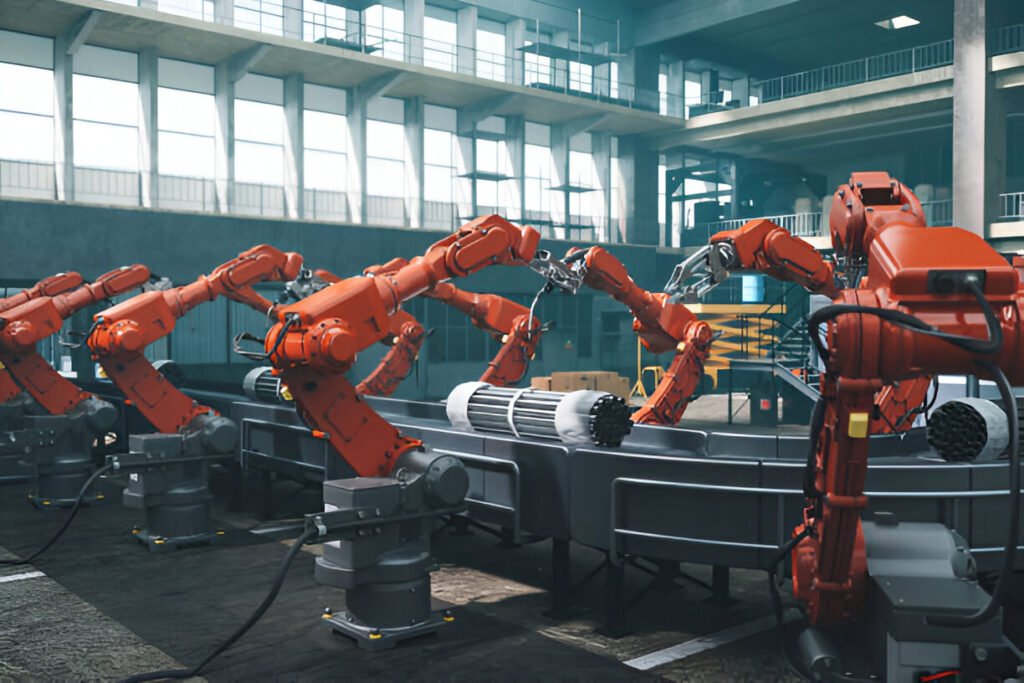

3. Smart Manufacturing Systems

Advanced robotics and AI-powered machinery can adapt to produce customized items without requiring significant retooling. For instance, AI can dynamically adjust production parameters on the fly, enabling factories to switch between different product variations seamlessly. This eliminates the traditional inefficiencies associated with small-batch production.

4. Predictive Maintenance and Quality Control

AI ensures that customization doesn’t come at the expense of quality. Machine learning algorithms can predict equipment failures before they occur, minimizing downtime. Similarly, AI-powered quality control systems use computer vision to identify defects in real time, ensuring that every custom product meets stringent quality standards.

5. Personalized Customer Experiences

AI also enhances the customer experience. Interactive tools like virtual try-ons, product configurators, and AR/VR applications allow customers to visualize and customize their products in real time. AI algorithms then translate these preferences into precise manufacturing instructions, bridging the gap between imagination and production.

Case Studies: AI in Action

Nike By You

Nike’s “Nike By You” platform leverages AI to offer customers the ability to design their sneakers. By integrating AI into the design and manufacturing process, Nike can deliver personalized footwear with a turnaround time that was unthinkable just a decade ago.

Tesla’s Customization

Tesla uses AI to streamline the customization of its electric vehicles. From choosing interior features to tailoring performance metrics, customers have extensive options, all facilitated by AI-driven manufacturing systems that adapt in real-time.

The Road Ahead

As AI continues to advance, the possibilities for custom manufacturing will only expand. Emerging technologies like AI-driven 3D printing, digital twins, and blockchain for supply chain transparency are set to redefine what’s possible. Shortly, consumers may be able to co-create products with AI systems, blurring the lines between designer, manufacturer, and end-user.

Challenges to Overcome

Despite its potential, custom manufacturing with AI is not without challenges. Data privacy concerns, the high cost of implementing AI technologies, and the need for skilled workers to manage these systems remain significant barriers. Companies must also navigate the ethical implications of AI-driven personalization, ensuring that algorithms do not inadvertently reinforce biases or exclude certain consumer groups.

Conclusion

AI is empowering manufacturers to deliver personalization at an unprecedented scale, transforming the custom manufacturing landscape. As businesses embrace these technologies, they’ll not only meet the growing demand for bespoke products but also unlock new levels of efficiency, creativity, and customer satisfaction. The fusion of AI and manufacturing is more than a trend—it’s the future of personalization.